X-ray protective clothing, including purpose-built apron screening systems, plays a pivotal role in reducing radiation exposure for both healthcare workers and patients during medical procedures. Be that as it may, the adequacy of these can be compromised by wear and tear over time, possibly imperiling patients and medical professionals.

What is a PPE test?

Testing X-ray personal protective equipment includes surveying the effectiveness of the pieces of clothing in protecting against radiation exposure. This could be done through different methods, counting:

- Visual inspection. Inspecting the protective clothing for any signs of damage, such as tears, holes, or discoloration, which could compromise its protective capabilities.

- Palpation. The garment is inspected for breaks, tears, and discontinuities by palpating with the hands, and suspicious spots are marked.

- Fluoroscopy/X-Ray testing. Using a fluoroscope/X-Ray unit to simulate X-ray exposure and assess how well the protective clothing attenuates radiation.

- Dose measurements. Conducting dose measurements on a mannequin or human volunteer wearing the protective equipment to determine the level of radiation penetration.

- Material testing. Testing the materials utilized within the protective clothing for their radiation attenuation properties and durability.

Why is personal protective equipment testing so important?

In hazardous work environments, employees depend on personal protective equipment (PPE) to mitigate health and safety hazards, trusting that manufacturers` assurances about the performance of their products are dependable.

The evaluation of PPE sold or utilized in the European Union is mandated by the EU’s PPE Directive and the upcoming PPE Regulation. Similarly, PPE used in federally regulated workplaces in the United States must adhere to specific American National Standards and regulations set by the Occupational Safety and Health Administration (OSHA).

What solution does LINEV Systems offer for testing personal protective equipment against X-ray radiation?

Currently, to control the properties of protective clothing, medical X-ray installations or a method for determining the weakening properties of X-ray protective materials are often used.

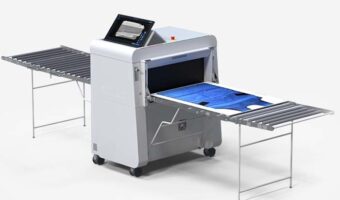

We have designed a purpose-built apron screening system which is intended for testing protective clothing and materials and we have named it FLOWD 8020 flaw detector. Innovative algorithms of processing the resulting images, developed by LINEV Systems specialists make it possible to obtain complete information about the homogeneity of the test materials, which, in addition to the standard procedure for determining the inhomogeneity parameter, opens up the possibility of introducing more capacious and informative characteristics.

The disadvantages of traditional method flaw detection are largely eliminated in the FLOWD. Its functions are based on X-ray scanning with the use of a fan beam of radiation and a linear detectors. Scanning large surfaces of an object with FLOWD allows any minor damage to the protective layer to be observed over the entire area of the object being inspected, as well as detecting and characterizing all larger ones with a probability — up to 100%.

In addition to this obvious advantage, FLOWD flaw detector implements a new high-precision method for determining the attenuating properties of materials, which has a number of advantages over the currently used one and may well form the basis for a new standard for determining the shielding properties of X-ray protective clothing.

The scanning and image processing procedures of FLOWD are based on the use of array detectors eliminating all serious problems associated with the use of ionization chambers. In particular, when using array detectors, there is no problem of the dependence of the detector response on the size of the irradiated area. In addition, taking into account the direction of radiation at each point of the detector during signal processing during detector calibration and measurements removes the requirement for a low beam divergence and eliminates its influence on the measurement results.

These advantages of the FLOWD flaw detector make it possible to count not only on its widespread use for testing X-ray protective clothing, but also open up the possibility of introducing new, simple and more accurate digital tools for checking the quality of X-ray protective materials and clothing.