Description

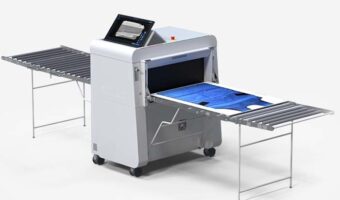

When it comes to vehicle industry, FLOWD is a helping hand. Its advanced scanning techniques allow for the thorough examination of sealed car door panels, making it an invaluable tool for vehicle manufacturers. Quick, accurate inspection of vehicle door panels with a minimum of labor costs and investment with FLOWD D – a compact, relocatable conveyor-type X-ray inspection system.

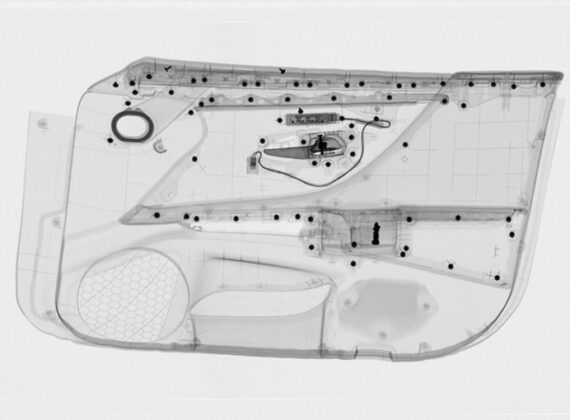

Car door panels, with their intricate mechanisms and concealed spaces, present a unique challenge for vehicle manufacturers. Small hardware components, like nuts and bolts, can occasionally go missing during assembly, potentially leading to operational issues or, at the very least, quality concerns.

Understanding the critical importance of maintaining excellence in the vehicle manufacturing process, we developed FLOWD D for inline and/or standalone Car Door Panels Inspection. This remarkable technology was conceived to assist vehicle manufacturers in their quest for uncompromising quality.

Our device employs advanced scanning techniques, providing a non-invasive solution for inspecting sealed car door panels. By utilizing FLOWD F, manufacturers can detect and locate lost small hardware components with unparalleled accuracy. This innovative approach ensures that every vehicle leaving the production line meets the highest standards of quality and safety, minimizing operational risks and upholding the reputation of excellence in the automotive industry.

Due to its compact and universal design, the FLOWD D can easily be relocated and deployed wherever inspections are needed. FLOWD D will fit through standard interior doorways, and its relocatable design is ideal for flexible use on the assembly line or at stand-alone locations.

FLOWD D system is a highly versatile tool designed to address the problem of lost elements inside the welded doors of vehicles. This highly innovative product allows for the inspection process to be carried out in-house. It is specifically designed for automotive usage and can be delivered directly to premises, with no need for additional tools or equipment.

Functions:

- Bi-directional scanning

- Secure login

- Multi-level user access with the ability to administer users, roles and access level

- Automatic diagnostics of the System and individual units performance

- Automatic warming up of the X-ray generator during prolonged idle time (no warming up is required during daily operation of the System)

- Automatic storage of X-ray images in the archive

- Object counter

- Display of date and time, unit serial number and operator ID

- Formation of service reports of the System

- Inversion of colours

- Black and white display mode

- Edge enhancement

- Display only organics and inorganics

- Adjustable gamma correction

- Contrast optimization

- Display of substances in accordance with the selected range of optical density

- Zooming in on images up to 96x

- View archive images

- Ability to save images to external media (flash drives) in proprietary format or JEPG

- Ability to convert X-ray images to .png format via a local network

Read lessRead more

Options:

- Detection of the items insde the door panels

- Automatic selection of suspicious objects

- Multilingual interface