Description

Testing of X-Ray protective clothing has become easy!

X-Ray protective clothing plays a pivotal role in reducing radiation exposure for both healthcare workers and patients during medical procedures. However, the regular wear and tear of these protective garments can compromise their efficacy. Existing inspection methods were imperfect and often unable to identify damaged areas, putting users at risk.

Driven by this challenge, we embarked on a journey to develop a purpose-built apron screening system that would ensure the highest standards of safety for medical professionals and patients. The result was FLOWD for X-Ray Apparel Inspection, a groundbreaking technology equipped with a unique algorithm that evaluates the actual condition of X-Ray protective properties. This innovation brought a new level of precision and safety to the medical field, making it possible to identify weakened areas with unparalleled accuracy.

FLOWD is a mobile testing machine designed to carry out quality control and protection level inspections on your X-Ray protection garments and accessories.

The machine is capable of testing various types of X-Ray PPE: aprons, skirts, vests, thyroid collars, etc. Moreover, the core protective material can be of any type: pure lead, leaded rubber, lead-free material, etc.

FLOWD doesn’t require special protective rooms, as its dose rate doesn’t exceed 1 μSv/h at any point at a distance of 0.1 m from the device’s outer surface.

Regular X-Ray protective clothing testing in compliance with din 6857-2 and ÖNORM S5213.

Options:

Peculiarities:

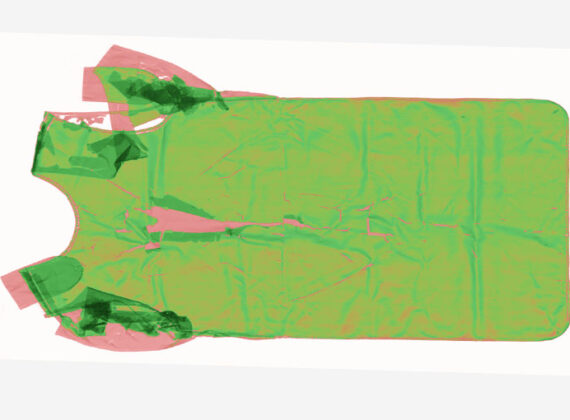

- Automatic detection

- Red-Green coloring

- Determination of lead equivalence

- Heterogenity calculation

Key features

Auto-detection of weak areas

Determination of lead equivalence

Full size image

Safety from X-ray radiation

Plug & Play

Enhanced mobility

Video

Technical data

X-ray unit

| Anode voltage | 80-100 kV |

| Anode current | 1,2-1,0 mA |

Inspection window

| Height | 240 ± 5 mm |

| Width | 870 ± 3 mm |

Dimensions of inspected object

| Width | 750 mm |

| Height | 200 mm |

| Length | 1300 mm |

Dimensions

| Overall dimensions | ||

|---|---|---|

| Width | 895 mm | |

| Height | 1630 mm | |

| Length | 1170 mm |

| Rollers & conveyor | ||

|---|---|---|

| Working length | 4080 mm | |

| Transporting length | 900 mm | |

| Maximum load | 25 kg |

| Weight (maximum) | 400 kg |

|---|

X-ray unit

| Anode voltage | 80-100 kV |

| Anode current | 12-10 mA |

Inspection window

| Height | 9.4″ ± 0.2″ |

| Width | 152.4″ ± 0.1″ |

Dimensions of inspected object

| Width | 29.5″ |

| Height | 7.9″ |

| Length | 51.2″ |

Dimensions

| Overall dimensions | ||

|---|---|---|

| Width | 35.2″ | |

| Height | 64.2″ | |

| Length | 46.0″ |

| Rollers & conveyor | ||

|---|---|---|

| Working length | 160.6″ | |

| Transporting length | 35.4″ | |

| Maximum load | 55.11 lbs |

| Weight (maximum) | 881.8 lbs |

|---|

Reviews and related links

X-ray protective clothing, in particular aprons, is widely used to reduce the radiation dose received by personnel during X-ray examinations. Currently, to control the properties of protective clothing, medical X-ray installations or a method for determining the weakening properties of X-ray protective materials are often used.

The design of the X-ray flaw detection system intended for testing such protective clothing and materials. Innovative algorithms of processing the resulting images, developed by LINEV Systems make it possible to obtain a complete information about the homogeneity of the test materials, which, in addition to the standard procedure for determining the inhomogeneity parameter, opens up the possibility of introducing more capacious and informative characteristics.

The fastest way to hear back from us is to fill the contact form below. Our appropriate department will get back to you depending on your inquiry as soon as possible.