We are now on the cusp of a new era of disruption. Modern problems of healthcare, ensuring the safety of people, improving the quality of life require the development of disruptive technologies that create new opportunities.

We work in partnership with our customers and look to solve their problems through innovation. We consider each appeal to us as a project, which we are ready to solve, exceeding expectations.

Our latest disruptive and breakthrough technologies for X-ray non-destructive testing are presented here.

BATTERAY - Inline x-ray battery sorting machines

Used batteries can be sorted into 6 different chemical groups

Batteries are no longer waste the environment and avoids getting into landfill

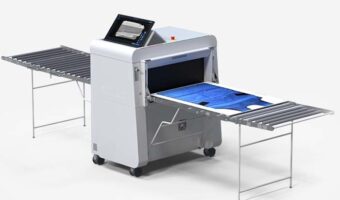

FLOWD - Multifunction x-ray inspection systems

Testing of X-ray personal protective equipment has become easy

New opportunities for prison mattresses and inmates belongings inspection

Searching various items inside sealed car door panels

Our latest disruptive and breakthrough technologies for X-ray non-destructive testing:

Innovative software solutions

Our unique AI competence, backed by numerous patents, has allowed us to begin the broad integration of AI technology into our innovative solutions. This has enabled us not only to create innovative products, but rather to bring cutting-edge technologies to market to ensure the safety and security of society to not only solve our customers’ problems, but also change the world.

Environmental protection – green technologies

The corporation has set itself the ambitious task of making a significant contribution to solving a major problem of our time – waste disposal. The innovative technology for sorting used batteries helps to reduce the pollution of the environment with the most hazardous metals. We have proposed a solution to the problem of identifying and removing lithium batteries when sorting paper waste, as they can be the source of fires in recycling plants.

Radiation safety of radiologists and patients

X-ray personal protective equipment (X-Ray PPE) is necessary to protect patients and radiology technicians from the damaging effects of scatter radiation and contact with open beam x-ray applications. Class-leading innovative mobile testing machine designed to carry out quality control and protection level inspections on your x-ray protection garments and accessories.

Prison crime prevention

Prison officers do an incredibly important job in an environment like no other. Mobile phones, in some cases can be just as dangerous as a weapon in a prison. Hundreds of our x-ray body scanners have been installed in prisons many countries; these scanners are capable of detecting not only cell phones, but drugs and weapons hidden in clothes and body cavities. Cells also regularly searched by prison officers. They look for drugs, other contraband, weapons etc. hidden in prison mattresses and inmates’ personal belongings. Realizing the complexity and danger of the work of prison officers, we have created a compact mobile X-ray inspection system for non-contact detection of all types of dangerous objects, wherever they are hidden.

Radiographic Testing, popularly known as X-ray or gamma-ray testing, is a non-destructive test method which makes use of the principles of radiation penetration in order to examine the internal structure of materials and components. In quite similar ways to X-ray examinations that are employed in the medical field but in an industrial materials test configuration.

Radiographic testing uses radiation to discover the presence of hidden imperfections, defects, and discontinuities in materials without causing any damage to the object under test. The basic principle of this test involves sending X-rays or gamma rays through a material and recording the resultant transmitted radiation onto a detector-usually a digital sensor. The image created shows the difference in material density:

- Internal cracks and voids;

- Porosity;

- Inclusions or foreign materials;

- Corrosion or wall thinning.

Since safety and reliability are cardinal parameters, the radiography test becomes indispensable in industries dealing with aerospace, automotive, oil and gas, and construction.

Key Benefits of Radiographic Testing in NDT

Flaw detection with accuracy

Internal structure flaws such as cracks, inclusions, or thinning can be detected by clear visual analysis with high precision.

Variety of materials may be subjected

Applicable on a wide scale to materials, including metals, composites, and polymers.

Three-dimensional volumetric testing

A 3D judgment about the integrity of materials will be provided due to detailed radiographs that include every part.

High-resolution imaging with clear results

The internal defects and/or material density variation are well viewed in interpretable images NDT X-ray.

Permanent inspection records

Creates durable inspection records (e.g., digital images or films with sensitivity indicators like IQIs) for future analysis and archiving.

High sensitivity

NDT X-ray machine detects minimal variations in material thickness and density—often as small as 1%—along the X-ray beam path.

The fastest way to hear back from us is to fill the contact form below. Our appropriate department will get back to you depending on your inquiry as soon as possible.

Get NDT X-ray equipment

Yes, radiographic testing is a totally non-destructive test. Both the X-rays and gamma rays allow the inspectors to “see inside” materials without physically damaging them; thus, making it an excellent inspection technique where components need to remain intact, such as in aerospace and manufacturing.

NDT methods are being applied in a wide range of industries outside the traditionally more obvious applications. For instance:

- Battery sorting: NDT systems can tell if a certain type of battery or any possible defects are identified without opening it.

- Security screening: for checking items like prison clothing against contraband concealment and the scanning of machine parts on customs against their material contents.

- Law enforcement: to conduct non-invasive analysis (non-destructive testing) of items that may include but are not limited to weapons, tools, and concealed storage machinery.

This ability of NDT methods to inspect without destruction makes them indispensable in both modern industries and emerging fields.