Description

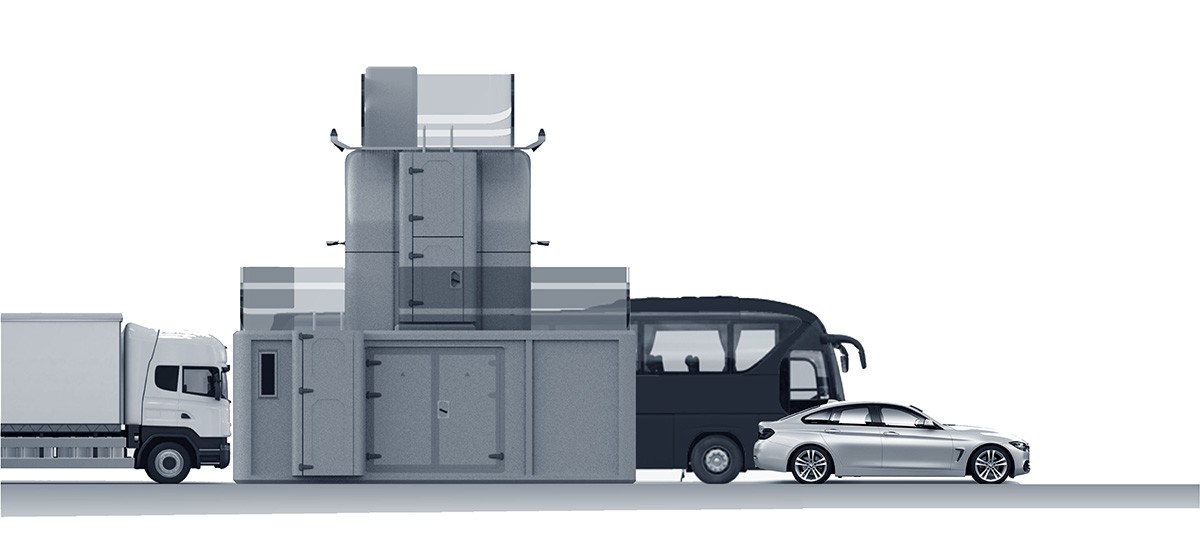

DTP 7500/320DV can be chosen for safe and rapid screening on the land border crossings for multi size vehicles inspection when several specialized solutions for different vehicles and loads are not applicable or not effective.

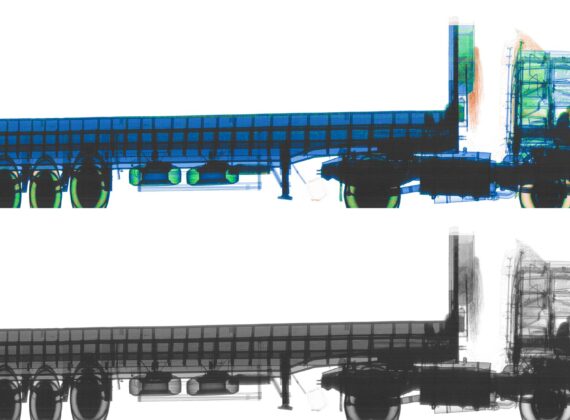

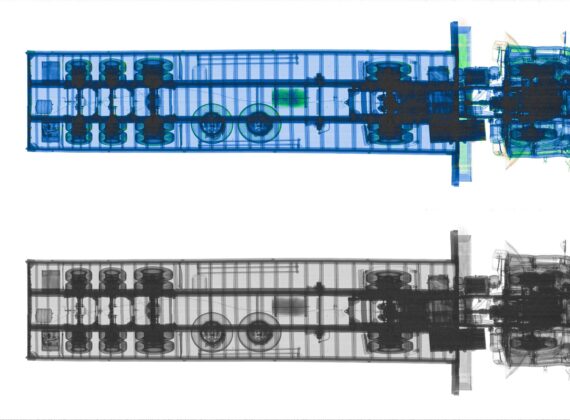

Light passenger cars alternating with loaded containers can pass through the system without any harm for the drivers. Vertical or horizontal projections can be used with a different optimal and safe energy levels. 320kV energy can be used for passenger vehicles, vans and buses with low density and 7.5 MeV can be used for the high dense loaded trucks.

Simultaneous application of both 320kV and 7.5MeV energies can significantly improve overall inspection level “opening” both low and high dense contraband and threats.

A dual-energy technology with automatic color coding and material discrimination allows distinguishing organic, non-organic materials and metals, and helps to highlight all dangerous and prohibited items and objects hidden inside the vehicles. The system helps to prevent illegal human trafficking, contraband and detect illegal drugs, weapons, explosives and other prohibited and dangerous objects.

Options:

- Weather package

- Automatic number plate recognition system (ANPR)

- Module for operator (control room) with conditioning system and operator`s workstations

- Remote station for image analysis

- Uninterruptable power supply for the whole system

- Integrated radiation portal monitor (IRPM)

- Under vehicle inspection system (UVIS)

- Diesel generator

Innovative drive-thru scanning technology

Dual-view technology

Dual energy technology with color-coding

High penetration: 320/60 mm

Screening of all types of vehicles with one portal

High throughput: 150 vehicles per hour

Technical data

Generator specifications

| Low-energy X-ray generator anode voltage: | |

|---|---|

| X-ray source 1 | 320 kV |

| X-ray source 2 | 320 kV |

| Low-energy beam direction: | |

| X-ray source 1 | Downward |

| X-ray source 2 | Lateral |

| High energy | 7,5 / 5,0 (MeV) |

| Maximum dose to driver (the driver’s cabin is not scanned) | <0,1 μSv/scan |

Unit specifications

| Dimension of inspection tunnel: | |

|---|---|

| Width | 3,5 m |

| Height | 4,7 m |

| Scanning speed | 5-15 km/h |

Operation

| Operating temperature | from -20 °С to +50 °С |

| Operating humidity | up to 90% |

Generator specifications

| Low-energy X-ray generator anode voltage: | |

|---|---|

| X-ray source 1 | 320 kV |

| X-ray source 2 | 320 kV |

| Low-energy beam direction: | |

| X-ray source 1 | Downward |

| X-ray source 2 | Lateral |

| High energy | 7,5 / 5,0 (MeV) |

| Maximum dose to driver (the driver’s cabin is not scanned) | <0,1 μSv/scan |

Unit specifications

| Dimension of inspection tunnel: | |

|---|---|

| Width | 11.5′ |

| Height | 15.4′ |

| Scanning speed | 3.1 – 9.3 mph |

Operation

| Operating temperature | from -4 °F to +122 °F |

| Operating humidity | up to 90% |

Reviews and related links

The fastest way to hear back from us is to fill the contact form below. Our appropriate department will get back to you depending on your inquiry as soon as possible.