LINEV Systems has established itself as a trailblazer in the field of benchtop science products. With a dedication to innovation, accuracy, and excellence, LINEV Systems is transforming the industry of science instruments by providing professionals, such as researchers and scientists, with cutting-edge solutions for their laboratory requirements. LINEV Systems stands out for its commitment to creating cutting-edge benchtop analytical equipment in an environment where science is becoming more demanding and fast-paced.

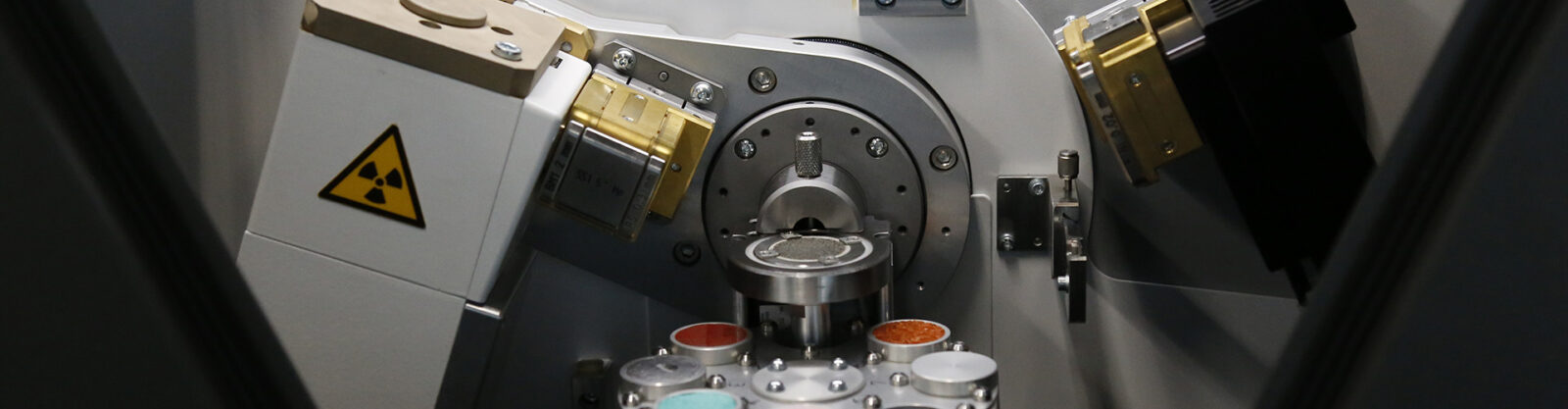

TELLUS — The All-in-One Solution

Multi-function solution with exceptional materials research & analysis speed, reliability and reproducibility

Sample Preparation

LOT #S1001 | Used for grinding and mixing various powders solid bulk substances

LOT #S1002 | The sampling sieve is used for the sieving of powders to separate consistent powders from lumps and solids during sample preparation.

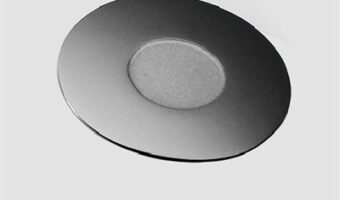

LOT #S1004 | The plates are used for leveling the powdered sample with the surface of the cuvette during reverse loaded cuvettes preparation for measurement.

LOT #S1003 | The plates are used in the preparation of measurement cuvettes to level the powdered sample with the surface of the cuvette.

Holders

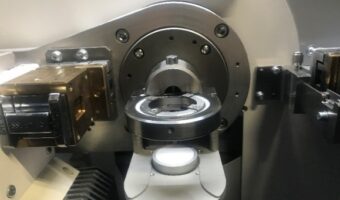

LOT #H1003 | An electromechanical assembly designed to install samples in circular cuvettes and rotate them at a specified speed during measurements

LOT #H1002 | Allows up to eight different samples to be loaded for measurements with rotation speed control of each sample

LOT #H1001 | For fixing bulk samples and leveling of the analyzed sample plane with the diffractometer plane.

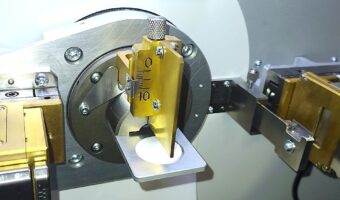

Knife-collimator

LOT #K1000 | Automated knife-collimator

LOT #K1001 | Indispensable accessory for high-accuracy measurement at narrow diffraction angles

Cuvettes

LOT #C1008 | For direct filling (with pre-levelling) of a powdered sample

LOT #C1005 | Backfilling and pressing powders in the pit

LOT #C1006 | Backfilling and pressing powders in the pit

LOT #C1004 | Direct filling of powdered samples and measurements using the sample rotator or automated sample changer

LOT #C1003 | Direct filling of a powdered sample

LOT #C1002 | High-precision measurement of small sample amounts

LOT #C1001 | Both direct and backfilling of powdered samples with the possibility of adjusting the loading depth

LOT #C1007 | For installing reference samples or background-free cuvettes

Alignment elements

LOT #A1003 | Forming a small, low-divergence radiation beam

LOT #A1003 | Aligning the X-ray diffractometer

LOT #A1002 | Beam intensity limitation during alignment

LOT #A1001 | Checking the diffractometer alignment and calibration with the software

Optical elements

LOT #O1005 | Limits the size of the beam in the axial direction

LOT #O1004 | Limits the incident beam equatorial divergence so that its projection on the test sample (footprint) has the specified dimensions and does not exceed the dimensions of the sample

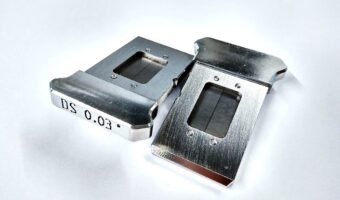

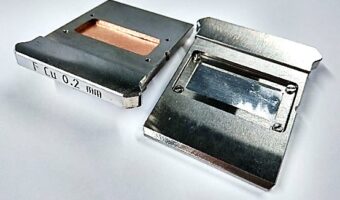

LOT #O1003 | Are installed into the incident beam mask socket (instead of BM1) and have numerical markings that coincide with the DS divergence slit markings

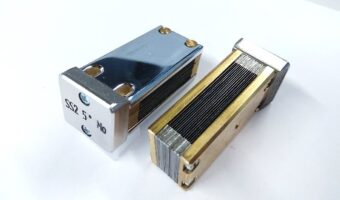

LOT #O1002 | Limit the axial divergence of the beam

LOT #O1001 | Limit the axial divergence of the beam

X-ray Tubes

LOT #X1002 | Forming radiation of different wavelength from 0,71 to 2,29 Å.

LOT #X1001 | Radiation monochromatization for selective suppression of the X-ray tube Kβ

X-ray diffraction (XRD) is a valuable laboratory technique used in materials research to investigate various materials’ chemical composition and crystal structure. It provides detailed information on properties such as crystal orientation, crystallite size, lattice strain, preferred orientation, and layer thickness without causing damage to the sample. Scientists rely on XRD for its versatility in analyzing a wide range of materials, including powders, solids, thin films, and nanomaterials.

The basic working principle of an X-ray diffractometer involves the following steps:

The diffractometer contains an X-ray tube that emits a monochromatic X-ray beam with a specific wavelength, such as copper Kα radiation (λ = 1.54 Å). The X-rays are directed towards the sample being analyzed.

The sample, typically in the form of a powder or single crystal, is mounted on a sample holder. The sample holder can be rotated to different angles to expose different crystal planes to the incident X-ray beam.

When the X-rays interact with the crystal lattice of the sample, they are diffracted by the atomic planes within the crystal structure. The diffracted X-rays form a diffraction pattern, with peaks corresponding to the angles at which constructive interference occurs between the scattered X-rays.

A detector positioned opposite the sample collects the diffracted X-rays and generates a diffraction pattern. The detector records the intensity of diffracted X-rays as a function of diffraction angle.

The diffraction pattern is analyzed using specialized software to determine the crystal structure, phase composition, lattice parameters, and other material properties. By comparing the diffraction pattern with reference patterns in databases, researchers can identify the crystalline phases present in the sample.

The results obtained from XRD analysis are interpreted to gain insights into the material’s structure, composition, and properties. The diffraction data can be used to study the material’s phase transformations, defects, texture, and other characteristics.

X-ray diffractometer enables scientists and researchers to investigate the atomic arrangement within crystalline materials and obtain valuable information about their structural properties through XRD analysis.

The fastest way to hear back from us is to fill the contact form below. Our appropriate department will get back to you depending on your inquiry as soon as possible.

Get XRD diffractometer

Benchtop X-ray diffractometers offer several advantages over larger, more traditional XRD instruments, making them a popular choice for many laboratories and industrial settings. Some of the key benefits of benchtop XRD systems include:

- Compact size: tabletop XRD instruments are significantly smaller and more portable than traditional floor-standing XRD systems. This compact size makes them ideal for labs with limited space or for on-site analysis in various locations.

- Ease of use: Desktop XRD systems are designed to be user-friendly, with simplified sample loading procedures and intuitive software interfaces. This ease of use allows operators with varying levels of expertise to set up and run analyses quickly.

- Quick analysis: Tabletop XRD instruments typically have faster analysis times compared to larger XRD systems. This rapid analysis capability enables users to obtain results quickly, making benchtop XRDs suitable for high-throughput applications.

- Low Maintenance: Desktop XRD systems often require less maintenance than larger instruments, reducing downtime and operational costs. They may also have self-diagnostic features that help identify and troubleshoot issues efficiently.

- Cost-effective: Tabletop XRD instruments are generally more affordable than traditional floor-standing XRD systems, making them a cost-effective option for labs with budget constraints or those looking to add XRD capabilities without a significant investment.

- Versatility: Despite their compact size, benchtop XRD systems can still provide high-quality data and are suitable for a wide range of applications, including phase identification, quantitative analysis, and crystal structure determination.

Benchtop X-ray diffractometers (XRD) are versatile instruments that can be used in various settings for different applications. Some common places where benchtop XRD instruments are used include:

- Research laboratories: Benchtop XRD is commonly found in academic and industrial research laboratories where materials analysis, crystallography, and structural characterization are performed.

- Quality control laboratories: Industries such as pharmaceuticals, chemicals, and materials manufacturing use benchtop XRD instruments for quality control and process monitoring to ensure the consistency and quality of their products.

- Educational institutions: Benchtop X-ray diffraction (XRD) is used in universities and colleges for teaching, allowing students to learn about crystallography, phase identification, and material characterization.

- Geological and environmental research: Benchtop XRD instruments are used in geology and environmental science to analyze minerals, soils, and environmental samples for research and monitoring purposes.

- Forensic laboratories: Benchtop X-ray diffraction (XRD) can be used in forensic analysis to identify and characterize materials, such as drugs, explosives, and unknown substances.

- Art and archaeology conservation: Benchtop XRD instruments are used in art and archaeology conservation to analyze materials, pigments, and artifacts for preservation and restoration purposes.

- Pharmaceutical industry: Benchtop XRD instruments are used in the pharmaceutical industry for drug development, formulation analysis, and polymorph screening to ensure the safety and efficacy of pharmaceutical products.