Description

DTP 7500LV can be chosen for safe and rapid customs screening on the land border crossings, for the container inspection at the seaport or similar applications.

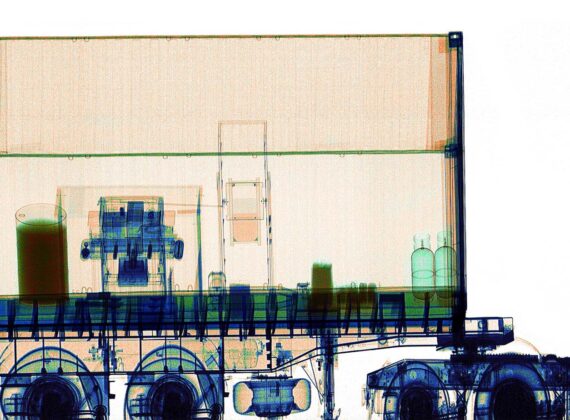

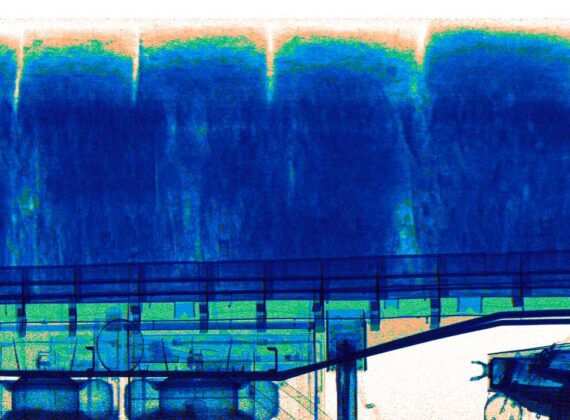

DTP 7500LV is a basic high energy x-ray inspection solution for loaded trucks and containers screening with minimal footprint and exclusion zone. It is a perfect for high density objects inspection and multiple threat and contraband detection when high throughput is vital for the customer. State-of- the-art innovative dual energy technology makes it possible to «see» trough more than 300 mm of steel, differentiate and highlight substances by their atomic numbers. Selective drive-through technology guarantees driver’s radiation safety, automatically preventing cabin inspection or significantly reducing radiation power coming to the cabin that allows a driver to stay safely inside his vehicle during inspection.

Software helps to highlight all dangerous and hidden objects inside the vehicles and have a ware range of tools for effective X-ray image analysis.

DTP 7500LV is an optimal solution for non-intrusive control of cargo at border check points, seaports and cargo terminals.

This system can be utilized as a cost-effective alternative for DTP 7500/320DV system that is a perfect drive through tool for all kind of threats independent on their thicknesses.

Options:

- Automatic number plate recognition system (ANPR)

- Container code recognition system for freight container numbers recording (ACCR)

- Under vehicle inspection system (UVIS)

- Integrated radiation portal monitor (IRPM)

- ID cards and passports reader

Drive-through and mobile scanning modes

Lateral projection

Dual energy technology with color-coding

High penetration 320 mm

High throughput 110 vehicles per hour

Reference Video

Technical data

Generator specifications

| Throughput capacity | up to 150 vehicles/hour |

| Steel penetration | up to 320 mm |

| Wire resolution (copper wire) | n 2 mm |

| Radiation dose to driver per scan | < 0,05 μSv (without scanning the cabin) |

| Number of projections | one, lateral |

Unit specifications

| Dimension of scanning vehicles: | |

|---|---|

| Length | 20,0 m |

| Width | 3,0 m |

| Height | 4,7 m |

| Dimension of inspection tunnel: | |

| Width | 3,5 m |

| Height | 4,8 m |

| Scanning speed | 5 – 10 km/h |

Operation

| Temperature: | |

|---|---|

| Operating | from – 20 °C to + 45 °C |

| With climatic package | from – 30 °C to + 55 °C |

Generator specifications

| Throughput capacity | up to 150 vehicles/hour |

| Steel penetration | up to 12.6″ |

| Wire resolution (copper wire) | 12 AWG |

| Radiation dose to driver per scan | < 0.05 μSv (without scanning the cabin) |

| Number of projections | one, lateral |

Unit specifications

| Dimension of scanning vehicles: | |

|---|---|

| Length | 65.6′ |

| Width | 9.8′ |

| Height | 13.1′ |

| Dimension of inspection tunnel: | |

| Width | 11.5′ |

| Height | 16.4′ |

| Scanning speed | 3.1 – 6.2 lbs |

Operation

| Temperature: | |

|---|---|

| Operating | from -4 °F to +113 °F |

| With climatic package | from -4 °F to +131 °F |

Reviews and related links

The fastest way to hear back from us is to fill the contact form below. Our appropriate department will get back to you depending on your inquiry as soon as possible.